AI to drastically cut time to develop new battery materials, say executives

Unlock the Editor’s Digest for free

Roula Khalaf, Editor of the FT, selects her favourite stories in this weekly newsletter.

Artificial intelligence can halve the time it takes to develop new battery materials, helping accelerate innovation to combat climate change, battery industry executives believe.

Mathias Miedreich, chief executive of Belgium’s Umicore, which is working with Microsoft, said that AI would have an “immense impact” on discovering and commercialising new battery materials.

In an interview with the Financial Times, he said: “The ambition is, when you have a certain product that you want to develop, to cut the time to market by half . . . we are doing now the first concrete projects to see if this is feasible.”

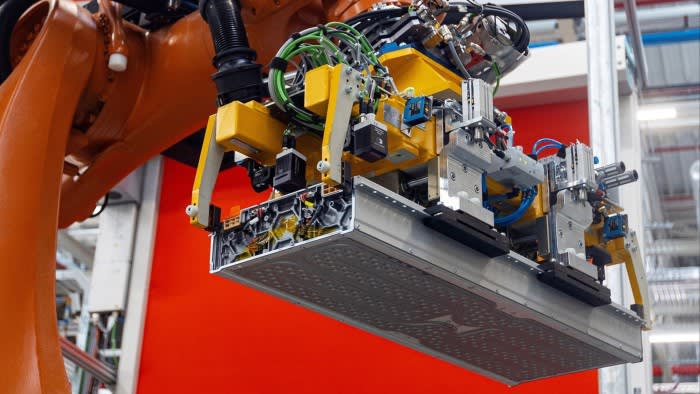

For the past two years, Umicore, supplied materials for car batteries used by companies such as Volkswagen, BMW and Stellantis, whose brands include Chrysler, Fiat and Peugeot.

He expected AI to help cut the research stage in developing new battery materials from five or six years to two years.

The partnership had allowed the company to file AI-enabled patents, said Miedreich. AI looked most promising for breakthroughs for solid-state materials and disorder rock salts, which would drastically improve the driving range of an electric car and open up new applications for batteries, he added.

Battery producers are optimistic of AI revolutionising the discovery of new materials, emulating a shift seen in the pharmaceutical industry where the technology is being used to speed up the development of new drugs.

“It’s going to be a substantial speed up in different phases of the process,” said Siddharth Khullar, a former Apple AI researcher who leads machine learning at Northvolt, the Swedish battery manufacturer.

“It’s like a recipe with multiple ingredients and we want to find out if the absolute ingredient is the right one or in the right proportion. This is a massive space to explore. With AI, you can start to expand the comfort zone of where you look.”

Earlier this month, Microsoft said that its work with the Pacific Northwest National Laboratory in the US showed that its algorithm was able to narrow 32mn materials down to 18 promising candidates to use in batteries in just 80 hours.

The government-backed laboratory is testing one of those materials, a hybrid of lithium and sodium, that could reduce lithium content by as much as 70 per cent — a material that automakers are worried will be scarce.

Venkat Srinivasan, director of the Argonne Collaborative Center for Energy Storage Science, a US government-funded laboratory, said that he was “pretty bullish” on AI’s impact on battery materials. That is because the advances in AI have come together with the automation of experiments with robots, allowing huge volumes of experimental data to be collected.

Miedreich cautioned that there might not be enough available computing power to make all the breakthroughs. And even if suitable materials are identified, researchers must test them in real-world conditions to discover whether they perform as hoped. The safety of batteries produced with new substances was also critical, meaning testing time was difficult to compress, said executives.

Nevertheless, with the US seen to hold a lead over China in AI, it could offer the west the chance to catch up with Asian rivals that dominate the global battery industry, one investor said.

“The US could try to use AI to optimise battery materials that they have access to and don’t need to rely on China for,” said James Frith, principal at Volta Energy Technologies, a battery supply chain investment vehicle.